Sponsored

Future View: Technologies that will transform the electrical industry

Mr. Lighting, Meet Miss HVAC

Lighting, HVAC and building automation companies are blending their products together into integrated building control systems that can dramatically slash the amount of energy a commercial building consumes. Earlier this year, GE Lighting announced details of its collaboration with Trane, where its LightSweep Modular Lighting Control Solution is being integrated into the TraneTracer building automation system. Trane’s Tracer BAS is a building automation system based on open standards that integrates building systems for maximum operational and energy efficiency. Its full mobile capability allows access and operation of the system from any laptop, tablet or smart phone.

The stakes are high — according to the American Council for an Energy-Efficient Economy (ACEEE), Washington, D.C., lighting and heating and air conditioning equipment (HVAC) account for 50% of all the energy that commercial buildings consume, and commercial buildings are one of the largest individual markets for distributors, manufacturers and reps, accounting for at least 19% of all products sold in the electrical wholesaling industry, according to EW data.

This integration of lighting into other building systems doesn’t stop with HVAC systems. GE also recently launched a series of LED lighting fixtures, the Lumination BL Series LED Luminaire, specifically for use in USG’s Logix Ceiling System. The press release announcing the launch says the fixtures are compatible with most other integrated ceiling systems in the marketplace today, and “help free architects and lighting professionals from the constraints of traditional t-grid ceiling designs.” These ceiling systems, it says, “reimagines lighting and utilities not as exposed fixtures, but contained within narrow bands running the length of the room.”

This allows designers to create ceilings with a clean, finished appearance that retain the functionality of T-grid systems for maintenance of HVAC, electrical and plumbing systems. GE says the integrated ceiling design cleans up the customary “patchwork” of intersecting 2’x2’, 2’x4’ and 1’x4’ T-grids.

New Players with New Ideas in the LED Market

In a related trend, look for more manufacturers from outside the electrical industry to set up shop in the LED end of the lighting market over the next few years. Over the past five years, Pacific Rim electronics and semiconductor companies like Sharp, Toshiba, and Panasonic made dramatic moves into the lighting market. Look for another giant industrial conglomerate, Honeywell, to get bigger in lighting, too, with its Jan. 2013 announcement that it was expanding its line of LED products through its new LED Lighting Solutions business unit. The company had been in LEDs since 2008 through its Honeywell Lonon joint venture, where it outfitted more than 100 Wal-Marts in China with LEDs, enabling each store to reduce energy usage by their lighting systems by half. LED lighting was installed for each store’s main floor, freezers, fresh produce section and outdoor billboard lighting.

With their backgrounds in the semiconductor, consumer electronics and building systems markets, these newcomers are strolling onto Electric Ave. with a clean slate when it comes to marketing their products. They may use existing channels, a blend of old and new channels, or an entirely different channel strategy. That’s both a challenge an opportunity for EW’s readers.

Using Gravity to Create Light

Word continues to spread about GravityLight, a new light source that uses an innovative weight, pulley and gearing system to generate the electricity needed to run a lamp for just over 30 minutes. Fast Companymagazine recently gave Deciwatt a 2013 Invention Award for the GravityLight. Users simply load the bag that comes with the unit with sand, soil or stones and attach it to the pulley system. As the bag descends it uses gravity to create the electricity needed to power the lamp.

London-based designers Martin Riddiford and Jim Reeves have spent the past four years developing GravityLight to provide residents of the world’s more remote areas with an inexpensive source of lighting that can replace the environmentally unfriendly kerosene lamps used in rural areas of Africa, India and other parts of the world. Riddiford and Reeves hope that when the GravityLight is in full production it will cost villagers less than $5 each.

Their research is funded in part by a crowdsourcing campaign at www.indigogo.com that raised $399,550 — including a $5,000 donation from Summit Electric Supply that qualified the Albuquerque, N.M.-based electrical distributor as a Terrawatt sponsor. This level of sponsorship means Summit gets its name or logo printed onto every GravityLight ballast bag sent to Africa or India, special mention on Deciwatt’s website and a demo unit. Deciwatt says it had a GravityLight prototype production run scheduled for the end of last month.

GravityLight is one of the most intriguing lighting products the editors have seen in quite some time. Even though it’s still in the developmental stage, Electrical Wholesaling’s editors wanted to bring it to the attention of our readers because it creates electricity in such a novel way and really makes you think about what other energy sources could be used to create electricity.

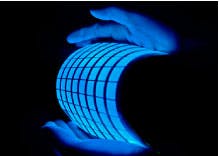

OLEDs: The Next Revolution after LEDs?

It’s been amazing to watch how quickly LEDs have moved into the lighting industry niche-by-niche. Although it took LEDs a long time to get very far past exit signs, over the past five years they have forever changed the municipal lighting, parking lot/parking garage, industrial high-bay fixture and other applications with high maintenance costs, and they may one day be a viable option for general office lighting. While their insanely long lamp life has been perhaps the biggest selling point of LEDs, their small form factor is also revolutionizing the design of lighting fixtures. They just don’t need the big, bulky housing of conventional fixtures and as long as they have a heat sink or some other method of cooling their electronic innards, some high-performance LEDs can operate quite happily for close to 50,000 hours.If you have been amazed by the fast growth and future potential of LEDs, you will be totally blown away by what OLEDs could do the lighting market if someone ever figures out a way to manufacture them cost-effectively. They are super-thin and some researchers believe they will one day be applied as a paint or another coating to walls, ceilings or virtually any other surface to light up a room. Heck, many researchers are already creating LEDs by literally spraying them on thin flexible substrates with inkjet printers.

As we reported in EW’s April 2012 cover story, OLEDs work by utilizing “a flat light-emitting technology made by placing a series of organic thin films between two conductors. When electrical current is applied, a bright light is emitted. OLEDs can be used to make displays and lighting. Because OLEDs emit light they do not require a backlight and so are thinner and more efficient than LCD displays (which do require a white backlight).”

A press release from The Optical Society, Washington, D.C., says a team of researchers at the University of Louisville is working to develop cost-effective OLEDs by combining OLEDs with “inorganic quantum dots,” which are tiny semiconductor crystals that emit different colors of light depending on their size. This R&D team is trying to develop an inkjet printing technique for mass commercial applications so manufacturers would spray quantum dots and OLED materials onto a surface that would emit light when connected to an electrical circuit. You see OLEDs in cellphone displays and cameras right now. Ten years from now distributors could be stocking and selling rolls of OLED-impregnated wallpaper to electrical contractors so they could help Harry Homeowner light up that man cave in his basement.

More Dependable Gusts of Power from Wind Turbines

In the world of renewables, life is good when the wind is blowing fast and the sun is shining brightest. The electricity that utility-scale wind farms or solar fields create is fed onto the grid and everybody is happy — unless the utility doesn’t need the power exactly when or where it’s being created by these wind turbines and PV panels. Then utilities have to look for a place to store this excess energy and bring it back onto the grid during those times when the sun isn’t shining or the wind isn’t blowing.

Being able to store electricity in batteries or other yet-to-be-created devices would smooth out the on-now, off-later power production of wind turbines and solar panels into a more dependable stream of electricity for electric utilities. GE Energy may have taken a step in this direction with the recent launch of its 2.5-120 GE Brilliant wind turbine, which it says is the first wind turbine to incorporate short-term battery storage as part of the complete turbine package. The 2.5-120 Brilliant wind turbine also harnesses the power of the Industrial Internet to analyze tens of thousands of data points every second, which helps manage wind variability and provides reliable, short-term predictable power while communicating with neighboring turbines, service technicians and operators. Invenergy recently ordered three of these units from GE as part of an 86-turbine deal for its Mills County, Texas, wind farm.

If researchers solve the puzzle of storing energy in mass quantities in batteries or other yet-to-be-invented methods, it could have huge implications for the world’s electrical grids. It would further decentralize the production of power, because anyone generating excess power could store it and sell it to the utility when it’s in demand. This would open the door to a new generation of “mini-power plants” that might require a massive retrofit of the electrical grid to handle the new generation. When you travel down the pipeline a bit into the electrical construction market, it could mean big business for any companies that sell and install electrical products for the new grid.

Centers of Battery Excellence

These advances in battery storage or some other method of storing electricity would have a trickle-down effect into other markets, as the development of lightweight, fast-charging and dependable batteries would create a whole a market niche in the supply and installation of electric-vehicle charging stations. The need for better battery storage has attracted the attention of the Department of Energy (DOE), and the federal government is funding the development of high-capacity storage batteries with the recent launch of what it calls its “Batteries and Energy Storage Hub” at the Joint Center for Energy Storage Research (JCESR) at the famed Argonne National Lab in Lemont, Ill. The lab, which received up to $120 million over five years, is focusing on applications in the transportation and the grid sectors. For electric vehicles, the Hub is looking for ways to increase power capacities and charges, and ways to quickly ramp up manufacturing this technology to full scale. In its grid research, the Hub is researching methods to integrate renewable energy sources like wind, solar and other intermittent sources onto the electrical grid so it would be able to dispatch electricity at the time when people need it the most.

You don’t hear as much about battery storage as you do about renewables like solar and wind. But the success of these two technologies is tied directly to the type of research that’s going on at this Hub. If the research teams at the Argonne National Lab, as well as at other R&D facilities working on battery storage accomplish their mission, we will be hearing a lot more about this critical technology.

The Smart Grid: Big Bucks or Big Talk?

It’s tough to say when or if the smart grid will ever live up to its potential, but there’s no doubt electric utilities are spending millions of dollars on the smart meters that will enable their customers to monitor their energy usage more closely. While some homeowners are fighting the installation of smart meters because they consider them to be an invasion of privacy, this network of smart meters would seem to be nothing but positive for the electrical wholesaling industry, because the information these meters collect may encourage consumers and businesses to install more efficient electrical systems. That’s obviously great news for distributors and their customers.

There’s more smart meters already installed than you probably realize. According to “Utility Scale Smart Meter Deployment, Plans & Proposals,” a report published in 2012 by the Edison Foundation, one in three households in the United States now has a smart meter and 22 electric utilities in 16 states have smart meters installed system-wide. The report also said that as of May 2012, 36 million smart meters have been installed and that 65 million smart meters will be deployed in total by 2015.

One of the larger installations is now underway at ComEd in Chicago, which recently announced that it would be purchasing approximately 4 million smart meters from GE over the next eight years in a deal worth more than $200 million. The smart meters will allow customers to better manage their energy usage and help ComEd detect and restore power outages more quickly. The press release announcing the deal said this installation is part of ComEd’s commitment to invest more than $2.6 billion over 10 years to modernize its electric grid in northern Illinois.

Super-Duper Solar Finally Becomes a Reality

Even solar energy’s stronger supporters must be a little disappointed that PV researchers haven’t yet figured out a way to create a super-efficient solar cell that makes financial sense so that the photovoltaics industry can exist profitably without the federal subsidies, utility rebates and other financial incentives it now needs for survival.It’s not for lack of trying, as research labs around the globe are buzzing 24/7 in a quest to develop a photovoltaic cell that can be applied not only in traditional rooftop solar panels and ground-mounted systems, but possibly in other parts of the exterior building envelope, including walls and windows.

Two university research teams are excited about some of the recent successes they have had in the development of the next generation of PV cells. Jeffrey Grossman and Marco Bernardi, two researchers at the Massachusetts Institute of Technology (MIT), think it’s possible to develop PV cells only one molecule thick, and they recently published a paper outlining their theories. According to a press release announcing the publication of their research paper, “Such panels, which have the potential to surpass any substance other than reactor-grade uranium in terms of energy produced per pound of material, could be made from stacked sheets of one-molecule-thick materials such as graphene or molybdenum disulfide.”

Jeffrey Grossman, the Carl Richard Soderberg Associate Professor of Power Engineering at MIT, said in the press release that the new approach “pushes towards the ultimate power conversion possible from a material for solar power.” Grossman is the senior author of the research paper published in the journal Nano Letters.

Across the country, researchers at the University of Wisconsin-Madison also recently announced two interesting developments in the solar field. Michael Arnold says his research team has developed an inexpensive solar cell that exploits carbon nanotubes to absorb and convert energy from the sun. Arnold, an assistant professor of materials science and engineering, said in a press release that their proof-of concept carbon nanotube solar cell can convert nearly 75% percent of the light it absorbs into electricity. “We’ve made a really fundamental key step in demonstrating that it will be possible to use these new carbon nanotube materials for solar cells one day,” he says.

In other solar news from BadgerNation, a UW-Madison electrical engineer has proposed a design for solar panels that can simultaneously generate power from sunlight and store power reserves for later, all within a single device. According to a press release announcing their research, Hongrui Jiang and his students developed the idea, which was the topic of a recent article in the journal Advanced Materials. Jiang is the Vilas Distinguished Achievement Professor of electrical and computer engineering at UW-Madison and specializes in microscale devices.

In their idea, the top layer of each photovoltaic cell is a conventional photo electrode, converting sunlight into electrons. Their design involves a standard-size solar cell that can simultaneously power a device and store energy for later use, creating a closed-loop system for small-scale applications of solar energy. “When there’s no sunlight, the stored power will come back through the nano wires to power the load,” he says. “We can have some energy set aside locally, right in the panel, so that when you need it, you can get it.”

You Want It? You Print It

If you have an eye for some of the hottest tech stocks on Wall Street these days, you are probably already watching or investing in companies like 3D Systems and Stratasys, which have taken the three-dimensional modeling of prototypes to the next level with printers that allow consumers and homeowners to “print out” an amazing array of products. The process is simple. Design a product with CAD (computer-aided design) software, and send that design to the printer. Today, these 3D printers use resins similar to what’s used in injection-molded ABS plastics to produce actual products and prototypes (like the jet turbine in the photo from Stratysys), and it doesn’t take too much imagination to see that it’s already quite possible to print out plastic products like cable ties, receptacle boxes and non-metallic fittings. These printers already produce caps and crowns in the dental industry; parts in the aerospace and defense industries; prosthetics; and all sorts of injection-molded plastic products.While it’s tough to imagine that an electrical contractor will ever use a 3D printer on a jobsite to print out a few junction boxes or cable ties, as 3D manufacturing matures and developers figure out how to expand the types of materials their printers can use, the sky’s the limit on what could be produced. There’s talk NASA has already figured out how to “print out” food for space missions, and at that least one 3D researcher has already printed out chocolate for his wife.

I hope you enjoyed the article. If I missed any trends, please give me a shout at 913-967-1743 / [email protected]. We would be glad to publish any additional trends that you think could have a big impact on your business.