Sponsored

In this post-recession world, electrical distributors are more concerned than ever about the disturbing long-range trend of U.S. manufacturing moving offshore. Many companies that have historically depended on the industrial market for their livelihood have had to recalibrate their customer mix and find new business to replace the sales dollars they lost when industrial plants in their market areas closed down and moved to less-expensive manufacturing locales in the Pacific Rim or elsewhere. While it’s inevitable that some U.S. manufacturers will search for offshore locations for their plants that offer fewer taxes and more incentives, some manufacturers, distributors and government agencies are taking a stand against this trend.

Last month, GE announced plans to invest $30 million and add more than 150 jobs in its domestic lighting manufacturing operations for GE Energy-Efficient Soft White light bulbs that will be sold exclusively at 3,400 U.S.-based Walmart stores. Recruitment and hiring for the new manufacturing positions will occur over the coming months at three GE plants in Bucyrus and Circleville, Ohio, and Mattoon, Ill. These new positions add to the more than 700 employees currently at work across the three plants. Production of the domestically made bulbs will start the first half of 2014. GE Lighting operates its global headquarters and 17 plants and distribution centers — more than half of its global manufacturing footprint — in the U.S.

In announcing the move, GE Chairman and CEO Jeff Immelt said in a press release, “As a company whose history dates back more than 130 years, we understand that to grow, we have to invest — in R&D and in workers. This announcement is evidence of our continued commitment to creating advanced manufacturing jobs in the U.S. and is yet another sign of an American manufacturing renewal.”

This announcement coincided with Walmart’s announcement that it had committed to buying $50 billion more in American-made products over the next 10 years, a move that it estimates will infuse more than $70 million into factory growth and create 1,000 domestic manufacturing jobs. Walmart made this commitment public last month at its U.S. Manufacturing Summit in Orlando, which was attended by approximately 1,500 of its suppliers and government officials.

More than any other niche in the electrical manufacturing industry, the lighting industry in general and the LED segment in particular may now face the biggest challenge of maintaining a U.S. manufacturing presence. LEDs are revolutionizing the lighting business niche-by-niche, and semiconductor manufacturers with factories in low-cost locales throughout the Pacific Rim that already dominate the electronics industry in the manufacture of cell phones, televisions, computers and other digitally-based products have a massive infrastructure in place to do the same to the LED market.

A group of U.S.-based lighting manufacturers and industry executives active with Department of Energy’s (DOE) Energy Efficiency & Renewable Energy (EERE) program believe it’s critical that lighting manufacturers continue their R&D efforts in the United States and maintain their U.S. factories producing LEDs. In recent years, several LED manufacturers have been in their news because of their expansion efforts in this country. Cree Inc., Durham, N.C.; Lighting Science Group (LSG), Satellite Beach, Fla.; and GE Lighting Solutions, Hendersonville, N.C., had all made sizeable investments in their domestic lighting operations.

A white paper published two years ago by the DOE’s Energy Efficiency & Renewable Energy Program, Keeping Manufacturing in the United States, says LED manufacturers in China and other Pacific Rim countries can manufacture products less expensively because of the following reasons:

- Proximity to the world’s highest population and supply chain

- Incentives offered for foreign investment in manufacturing and R&D, such as government subsidies to defray the cost of energy and water

- Export incentives, tax breaks and tariff protection from foreign competition

- Lower wages

- Local rules and regulations

- Major funding for research and development

The white paper outlined several recommendations on what it would take to grow the LED manufacturing industry in the United States and included some interesting comments by Jim Anderson, director of strategic marketing, Philips/Color Kinetics, about what it would take to establish a larger domestic manufacturing presence. He said in that white paper that the U.S. LED industry would need the following:

- A location where labor is only 3 to 5 percent of the end cost of producing a high-power solid-state light engine

- Highly automated and flexible factories to allow for lower cost ‘just-in-time” manufacturing. If they are done right they can also improve quality and statistical process controls.

- Strong local infrastructure industries that provide materials and component parts and the other building blocks necessary for market success

- Government incentives and tax credits

- A strong local market for lighting products.

Over the past few years, the DOE has provided matching funds to LED manufacturers expanding R&D facilities in the United States in the form of its “Solid-State Lighting Manufacturing Funding Opportunity” program. In its most recent fourth round of funding, the DOE provided $10.1 million in matching funds for five companies involved with solid-state R&D lighting projects: Cree Inc., Durham, N.C.; Eaton Corp., for a facility in Menomonee Falls, Wis.; OLEDWorks, Rochester, N.Y.; Philips Lumileds Lighting Co., San Jose, Calif.; and PPG Industries, Pittsburgh, a manufacturer of OLEDs. If you are interested in learning more about the DOE’s activities to keep lighting manufacturing in the United States, check out the “SSL in America” series in the free email newsletter SSL Postings. To subscribe contact DOE at [email protected].

The Local Touch

For some U.S.-based electrical manufacturers, “Buy American” is much more than a marketing message — it’s personal. In Connecticut, the Aurays of Bridgeport Fittings have seen many businesses move out of the state to less-expensive manufacturing regions in the United States or out of this country altogether. As the owners of a family business located in Connecticut for 88 years, they feel a strong attachment to the local community. Nearly three-quarters of their products are manufactured in their Stratford, Conn., facility, which employs 200 workers. A video that they recently published (see link on ewweb.com) succinctly summarizes their Buy American views. In a press release announcing the launch of the video, Tom Auray executive vice president, said, “With so many manufacturers outsourcing virtually all of their production overseas, a problem with quality and delivery eventually emerges. This is not the way at Bridgeport. We believe our business can only be successful by keeping our manufacturing base here in the U.S. where we can offer customers superior products and services, while remaining price competitive through efficiencies and smart manufacturing. This differentiates us from the competition and is a source of great pride, which makes us even more committed to providing our customers with the greatest possible value.”

His brother Del, the company’s CEO, says in the video, “We saw that more and more products were being made overseas and those products were being made very cheaply. As costs were going up, people were making a lot of money with those products. They were having a lot of problems, too, with quality. I thought about that and I realized that selling a cheap product wouldn’t be the way our business would be successful. We would have to focus on the things that made us great — service, quality and delivery. And really focus on continuing to make products here. And that would differentiate us from the competition… Being a Connecticut-based manufacturing company is something I am very proud of.”

Bridgeport also offers a list of projects where its U.S.-made fittings were installed on federal projects and schools as part of the American Recovery and Reinvestment Act of 2009, which required the use of U.S.-made products in some federal projects.

Ideal Industries, Sycamore, Ill., has also proudly promoted its American-made products. The company added to its domestically produced products with the acquisition of three hand tool manufacturers that manufacture their products in the United States — SK Hand Tools Corp., Chicago; Western Forge, Colorado Springs, Colo.; and Pratt-Read, Shelton, Conn. At the time of the Pratt-Read acquisition, Jim James, Ideal Industries’ CEO and president, said in a press release announcing the deal, “Acquiring Pratt-Read in addition to Western Forge enhances the capabilities of Ideal and expands the product offering in the hand tool market to further emphasize our strong, strategic focus on American-made quality, service and value.”

Passionately American Distributors

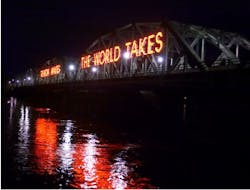

There’s still a strong current of “Made in America” sentiment running through some electrical distributors, too. For instance, Bill Goodwin, the president of Griffith Electric Supply, Trenton, N.J., also takes the Buy American Movement personally. He says he has always “bled red, white and blue,” and that he has seen many manufacturers move out of the Trenton market area over the past few decades who were once the customers of the company that Bill and Meta Griffith started up in 1938. In its day, Trenton was a major manufacturing center and was home to several electrical manufacturers that have since shuttered their facilities, including Roebling Wire Works, which was right across the street from Griffith Electric, and Heinemann Electric. A bridge across the Delaware River that connects Trenton to the northern Philadelphia suburbs still bears an illuminated sign that once proudly proclaimed “Trenton Makes, The World Takes,” but Goodwin says he sometimes thinks that now that only thing the world takes from Trenton is manufacturing jobs.

Goodwin has always made sure Griffith Electric Supply supported the U.S. electrical manufacturers that kept manufacturing jobs in the United States, and when he saw an ABC World News special by Diane Sawyer several years ago about Anders Lewendal, a homebuilder from Bozeman, Mont., who built a house using only American-made products, he wondered how many of his customers would think about increasing their use of U.S.-made electrical products., too. (See sidebar on p. 18).

He and Ron Lim, the company’s V.P. of sales, discussed the concept and went to Creative Marketing Alliance (CMA), Princeton Junction, N.J., to help develop the “Powered By America” campaign that they now use to encourage customers to purchase products made in the United States. The campaign included a website (www.poweredbyamerica.net); a trade show in which manufacturers displayed select electrical equipment that was produced in U.S. factories; a contest for the trade-show exhibitor that did the best job supporting the “Buy American” theme; and promotions to the company’s customers in New Jersey, Pennsylvania and Delaware featuring the electrical manufacturers that helped sponsor the program. In addition, CMA produced a Powered By America video that featured the role Griffith Electric Supply had played in supporting and supplying the Trenton area’s manufacturing community over the years.

Goodwin says the Powered By America program was a great moral boost for the company’s employees. “The question often comes up: ‘Did you make any money on the program? Did it increase sales?’ That was really never our intent. Obviously, if it increased sales we weren’t going to turn it down. Our intent was to help American manufacturers and do our part, as little as it may be. It gave our employees something to feel good about. This was done when times were bad, after the recession started. You needed to give people something to feel good about.”

As he explained in a press release announcing the campaign, “As a proud and hard-working family company, we understand what goes into running a successful business. Powered by America is designed to support other U.S. companies and individuals like us who are proud of their country and want to see it prosper competitively once again.

“Griffith was established in the once thriving manufacturing hub of Trenton, while the United States was also titled ‘the world’s leading manufacturer.’ Griffith Electric aims to play a part in restoring such esteem to the country and the domestic job market for working Americans. In so many ways, Powered by America has the opportunity to shape positive growth for our country. We salute American manufacturers and encourage our country’s loyalty to them.”

The electrical manufacturers that supported the Powered by America campaign included Arlington Industries, Bridgeport Fittings, Cooper B-Line, Crescent/Stonco (Philips), Eaton-Cutler Hammer, Erico-Caddy, General Cable, Hoffman, Hubbell Lighting, Hubbell Wiring Device-Kellems, Ideal Industries, Leviton, Lutron, Milwaukee Tools, Osram Sylvania, RAB Lighting, Siemens, Simkar, Southwire, Thomas & Betts and TPI Corp.

Goodwin says at least one other electrical distributor liked the concept of Griffith Electric Supply’s Powered By America program enough that he asked them if he could borrow the idea for his company. Warren Janes, V.P. of sales and marketing, Maurice Electric Supply, Washington, D.C., developed a similar program with the assistance of CMA called AMP (American Made Pride) (www.americanmadepride.net). The program offers the company’s customers a number of incentives to buy U.S.-made electrical products. A promotional email on AMP that was sent out in July said, “At Maurice, we make choices every day. We can choose to buy an offshore item and stock it, or we can choose to support American jobs. We can choose our manufacturer partners based on price alone, or we can choose a partner with factories in the USA and the best service. We try to think American-Made first.

“You have choices when you buy products for your job. You can buy from offshore electrical supply (houses) or you can help secure American jobs. You can buy from foreign-owned electrical supply (houses) or you can buy from American-owned and -operated Maurice Electrical Supply.

“We are finding that our AMP program is pushing our AMP vendors to work with us to be not just competitive, but the low-cost provider. The same can work for you. Work with us and we can provide both the low cost to you need and help secure American jobs. We hope you will join us and support American jobs. Together, we all win and the U.S. economy gets stronger. Think American Made First!”

The electrical manufacturers (or divisions of electrical manufacturers) participating in the AMP program include Allied Tube & Conduit, AFC, Cablofil/Legrand, Eaton, GE Energy, Generac, General Cable, Greenlee, Hubbell Lighting, Ilsco, Klein Tools, Lenox, Leviton, Lightolier, Lutron, Panduit, Pass & Seymour/Legrand, Picoma, Philips, Thomas & Betts, Wheatland Tube, 3M and Wiremold/Legrand.

There’s no doubt that the U.S. electrical manufacturing community has an increasingly global edge, and that electrical manufacturers around the world will continue to make their mark on this industry. But you can’t discount the fact that many distributors, independent manufacturers’ reps and their customers are still looking for ways to support U.S.-based manufacturers of electrical products.

The Story Behind the All-American Home Initiative

The ABC News report that inspired Griffith Electric Supply’s Bill Goodwin to launch his company’s “Powered by America” initiative had its roots the customer requests that homebuilders Anders Lewendal and Jake Lewendal were getting for the use of U.S.-made building products. According to that video report and information on their website, www.theallamericanhome.com, they built their first home using 100% American-made products in 2011. They thought about the impact this could have on the homebuilding industry as a whole, and decided to challenge other homebuilders to reallocate 5% of their spending for the purchase of domestically manufactured building products.

According to that website, “Determined to see this idea to fruition, the Lewendals sought the advice of other industry experts and economists, with Anders’ love for numbers and quantification continually driving their research. Ultimately, they received validation through the Boston Consulting Group, which determined that if every builder in America were to reallocate 5% of construction spending from foreign to domestic products, it would in effect create 220,000 American jobs. From there, the Lewendals were able to extrapolate that if every household in the United States reallocated just 5% of its yearly spending to American products, it would create 3 million American jobs. That’s when the All-American Home Initiative was officially born. Since that time, they have launched the All-American Home website and blog, encouraging Americans to support local manufacturing and to buy local as often as possible and created the “5% Club,” “where building industry professionals take a pledge to use at least 5% more Made-In-America products in order to help grow our Gross Domestic Product and create more American jobs.”

The electrical manufacturers that Lewendal lists on his website as providers of U.S.-made electrical products include Allied, Bridgeport, Broan, Cooper B-Line, Creative Illumination, Hi-Lite, Honeywell, Ideal, Juno Lighting/ Schneider Electric, Meyda Lighting, Sylvania and Thomas & Betts.

Some grim statistics on U.S. manufacturing

It’s tough to find many bullish numbers on U.S. manufacturing because it has suffered from such a dramatic decline over the past 15 years. Here are some statistics that tell a particularly painful story.

•The U.S. trade deficit with China eliminated or displaced more than 2.7 million U.S. jobs between 2001 and 2011. —Economic Policy Institute

•American manufacturing lost almost 6 million jobs between 2000 and 2010. —U.S. Bureau of Labor Statistics

•It’s 20% more expensive to manufacture in the U.S. than other countries, excluding labor. —National Association of Manufacturers